- Manufacturers & Suppliers of Electric Heating Elements For Industrial & Domestic Use

- +91 98150-61312

- +91 78885-37068

Best Aluminum/Bronze Manufacturer Tips to Reduce Heater Costs

Industrial heating systems are essential for manufacturing, processing, and production efficiency. However, rising energy prices and maintenance expenses can increase operational costs if heaters are not optimized. For businesses looking to improve performance while reducing expenses, understanding how to select materials, designs, and suppliers is crucial. Space Enterprises India shares expert insights to help industries cut costs without compromising heating efficiency or product quality.

Table of Contents

ToggleUnderstanding Heater Cost Factors

Before reducing expenses, it’s important to identify what contributes to heater costs. The total cost of an industrial heater includes raw materials, manufacturing quality, energy consumption, maintenance frequency, and lifespan. Aluminum and bronze components are widely used because of their excellent thermal conductivity and durability. Choosing the right alloy grade and design ensures faster heat transfer, which reduces power consumption and lowers long-term operational expenses.

Another key factor is build precision. Poorly manufactured heaters lose heat, require more power, and wear out quickly. Working with an experienced manufacturer ensures better engineering, which directly impacts energy efficiency and reliability.

Choose the Right Material for Efficiency

Material selection plays a major role in heater performance. Aluminum heaters heat up quickly and distribute temperature evenly, making them ideal for applications requiring rapid thermal response. Bronze heaters, on the other hand, offer superior strength, corrosion resistance, and long service life. Selecting the appropriate metal based on your application prevents unnecessary energy use and reduces replacement frequency.

Industries should consult experts before purchasing heaters to ensure the material matches operating conditions such as temperature range, humidity, and pressure. This prevents overheating, minimizes downtime, and extends equipment lifespan.

Work with Reliable Component Suppliers

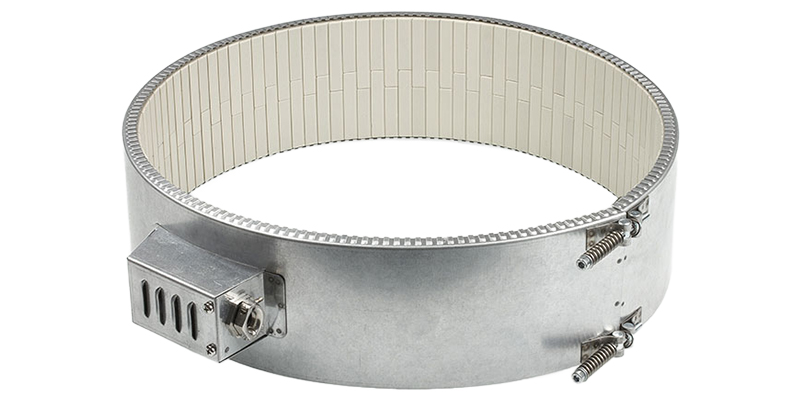

Choosing a trusted Ceramic Band Heater Supplier can significantly affect operating costs. Ceramic band heaters are known for excellent insulation and efficient heat transfer, which means less energy is required to maintain desired temperatures. High-quality ceramic insulation also reduces heat loss, allowing machines to operate at consistent performance levels.

Optimize Heater Design and Installation

Even the best heater can become inefficient if installed incorrectly. Proper installation ensures optimal contact between the heater and the surface it warms, which improves thermal transfer. Loose fittings or improper mounting can cause energy waste and uneven heating.

Manufacturers recommend using insulation covers, temperature controllers, and thermostats to regulate heat output. These additions may seem like an extra investment initially, but they reduce power consumption and prevent overheating, resulting in substantial savings over the long term.

Maintain Heaters Regularly

Routine maintenance is one of the simplest ways to reduce heater costs. Dust, residue, and oxidation can accumulate on heating elements, decreasing efficiency and forcing the system to consume more energy. Regular cleaning, inspection, and timely replacement of worn components keep heaters running at peak performance.

Scheduled servicing also helps detect small issues before they become major failures. Preventive maintenance costs far less than emergency repairs or production downtime, making it a smart strategy for cost control.

Invest in Energy-Efficient Technology

Modern heating solutions are designed with energy efficiency in mind. Advanced heaters include improved insulation materials, precision temperature sensors, and automated control systems. These technologies allow industries to regulate heat output based on real-time requirements, eliminating unnecessary power usage.

Upgrading to energy-efficient models from experienced aluminum and bronze manufacturers can dramatically reduce monthly electricity bills. Over time, the savings often exceed the initial investment, making it a financially sound decision.

Partner with an Experienced Manufacturer

Working with a trusted manufacturer like Space Enterprises India ensures access to high-quality materials, advanced engineering, and customized solutions. Experienced manufacturers analyze your operational needs and recommend heaters tailored to your processes. This personalized approach prevents overspending on oversized equipment or underperforming systems.

Reliable manufacturers also provide technical support, installation guidance, and after-sales service, all of which contribute to lower maintenance costs and longer equipment life.

Heating Coil Supplier

Similarly, partnering with a professional Heating Coil Manufacturer ensures precision-engineered coils that distribute heat evenly. Poorly designed coils often create hot spots, leading to product defects, higher electricity usage, and frequent replacements. Reliable manufacturers test their products rigorously to ensure durability and stable output, helping businesses save money over time.

Reducing heater costs is not about choosing the cheapest option—it’s about selecting the right materials, suppliers, and designs that maximize efficiency and durability. By working with expert manufacturers, selecting quality components, and maintaining equipment regularly, businesses can achieve consistent performance while controlling expenses. With the right strategy and guidance from Space Enterprises India, industries can enjoy long-lasting heating solutions that deliver both reliability and cost savings. Epping Taxi